Silicon Carbide Knife Sharpening Stone

Silicon Carbide Knife Sharpening Stone Company instruction: For more than 50 years, the ceramic honing stone, resin honi

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | GC |

| Type | Standard Oilstone |

| Material | Green Silicon Carbide |

| Application | Tool |

| Effect | Polishing |

| Feature | High Quality |

| Color | Grey |

| Usage | Grinding Knife |

| Grit | 240 |

| Model | Combinative Whetstone |

| Transport Package | Cartons |

| Specification | 100-25-15 |

| Trademark | iSharp |

| Origin | China |

| Production Capacity | 10000PCS/Month |

Product Description

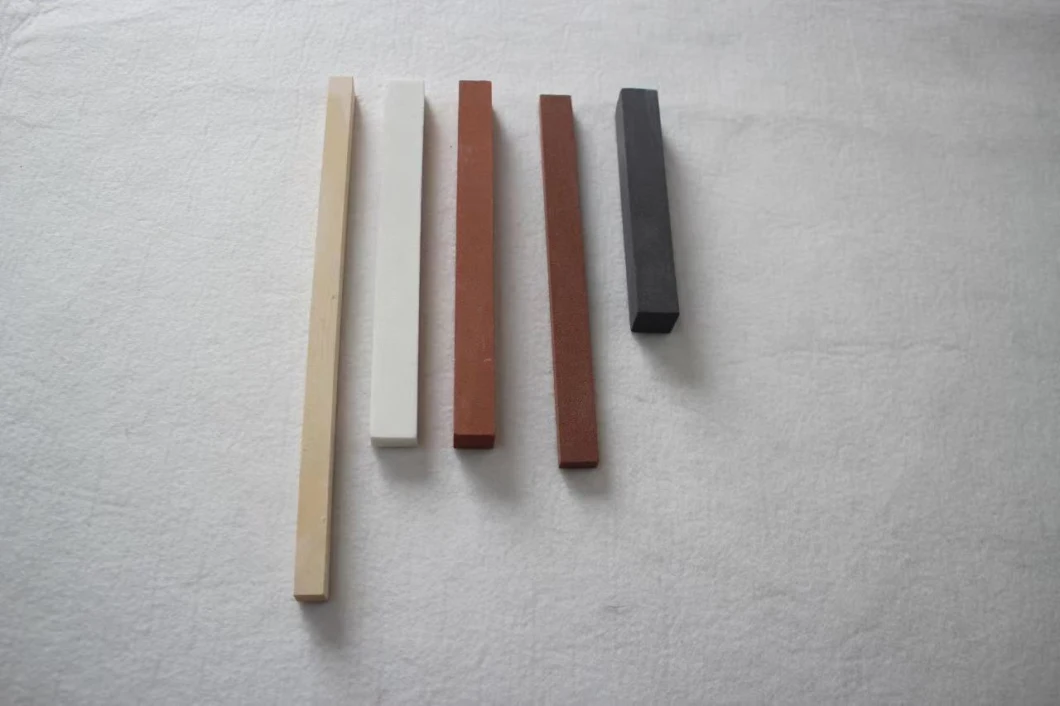

Silicon Carbide Knife Sharpening StoneCompany instruction:For more than 50 years, the ceramic honing stone, resin honing stone, wood powder honing stone, diamond honing stone and CBN honing stone produced by our company have stable quality, and the honing mesh has reached National VI and Euro VI standards. Our market share ranks the first in China. We are the domestic stable supplier of large-scale cylinder liner factories. Besides, our ultra-sharpening stone, sharpening stone, mould special sharpening stone and ceramic fiber oil stone are of excellent quality and are exported in large quantitiesProduct information:Application of Combination Knife Sharpening Stone:

The whetstone generally has a single-sided or double-sided design, the general family to prepare a double-sided whetstone is enough, there is no need to prepare more than a single-sided whetstone, the use of the side of the low number of eyes for sharpening and rough grinding, and the other side for polishing and finishing.

Advantages

- Free sample for general sharpening stone, uniform quality as first sample offered

- Sharpening dressing stone of various sizes, shapes, grits and applications are available.

- Factory direct, best price and shortest lead time for general sharpening stone

Abrasives: C/GC

Grit: 80#-600#

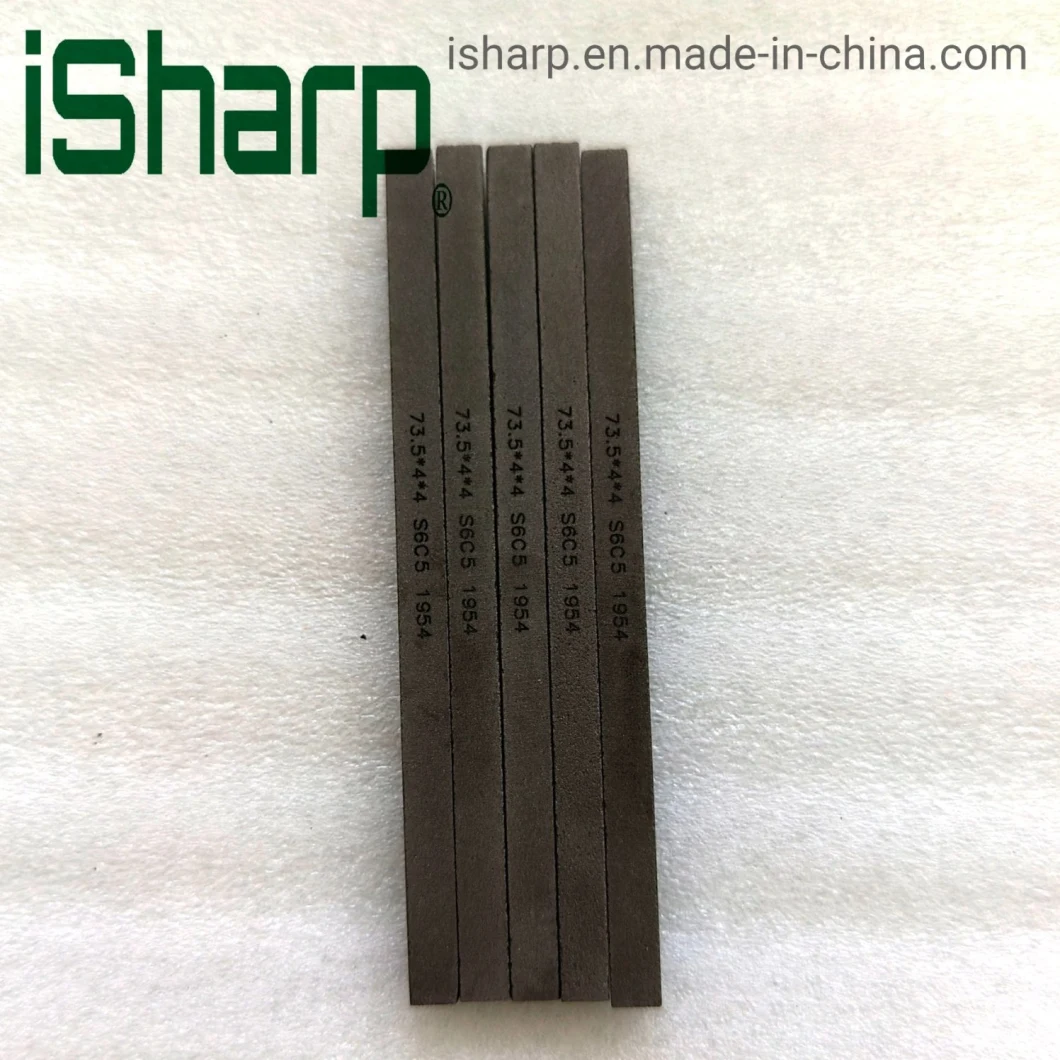

Length: 150-250mmModel: Combination knife sharpening stones

Details:

| Type | Length(mm) | Width(mm) | Thickness(mm) | Grit |

| Rectangular | 150 | 50 | 25 | 80,120,300 |

| 200 | 50 | 25 | ||

| 250 | 50 | 25 | ||

| 275 | 50 | 25 |

For the vertical grinding that pushes and pulls up and down, the same strength should be moderate, not too heavy or too light. Because the vertical grinding is on the same plane and there is no segment, it can smooth the unevenness of the horizontal grinding blade, so that we The kitchen knife will be very sharp when used.

Keep a uniform strength, it will take about four or five minutes to grind, turn over to the other side and continue to polish. Then wash the kitchen knife, and then dry the water. After vertical grinding and horizontal grinding, the blade is very smooth and very sharp.

Related Products

-

![China Manufacturer 4 Inch Steel Polishing for Power Tools Abrasive Calcined Aluminium Flap Disc]()

China Manufacturer 4 Inch Steel Polishing for Power Tools Abrasive Calcined Aluminium Flap Disc

-

![Non Woven Wheel, 200X50mm, U3/7p, Red Color]()

Non Woven Wheel, 200X50mm, U3/7p, Red Color

-

![Hot Dipped/Prepainted Galvanized Steel Coil/Sheet/Plate/Strapping/Strip Gi Gl/SGCC Dx51d Q195+Z Q235+Z]()

Hot Dipped/Prepainted Galvanized Steel Coil/Sheet/Plate/Strapping/Strip Gi Gl/SGCC Dx51d Q195+Z Q235+Z

-

![SGCC Z275 Dx51d Dx52D Dx53D 24 Gauge 26 Gauge PPGI PPGL 4X8 Hot Dipped Gi Galvanized Steel Coil/Sheet.]()

SGCC Z275 Dx51d Dx52D Dx53D 24 Gauge 26 Gauge PPGI PPGL 4X8 Hot Dipped Gi Galvanized Steel Coil/Sheet.